We’ve Moved to Our New Office! A Fresh Start for a New Chapter

In November 2025, we officially moved into our brand-new office and production facility.

This relocation represents more than just a new space—it marks a significant milestone in our company’s growth.

With brighter, more spacious environments, clearly defined departmental layouts, upgraded management systems, and improved workflow organization, we are better equipped than ever to deliver reliable, high-quality products to customers around the world.。

3D Printing Room — Where Efficiency Meets Precision

Our new 3D printing room is equipped with five Bambu Lab printers, all featuring automatic plate changing, enabling long-hour continuous operation with stable performance and higher productivity.

Additionally, three resin (SLA) printers support high-precision prototyping and small-part validation.

This space ensures rapid iteration and reliable engineering support for our product development.

Laboratory & Tea Area — A Space for Innovation and Relaxation

The upgraded laboratory features a more refined and scientific layout, allowing R&D, testing, and verification work to proceed smoothly and efficiently.

Adjacent to the workspace, we added a cozy tea and coffee corner, giving team members a place to relax, recharge, and spark new ideas during casual conversation.

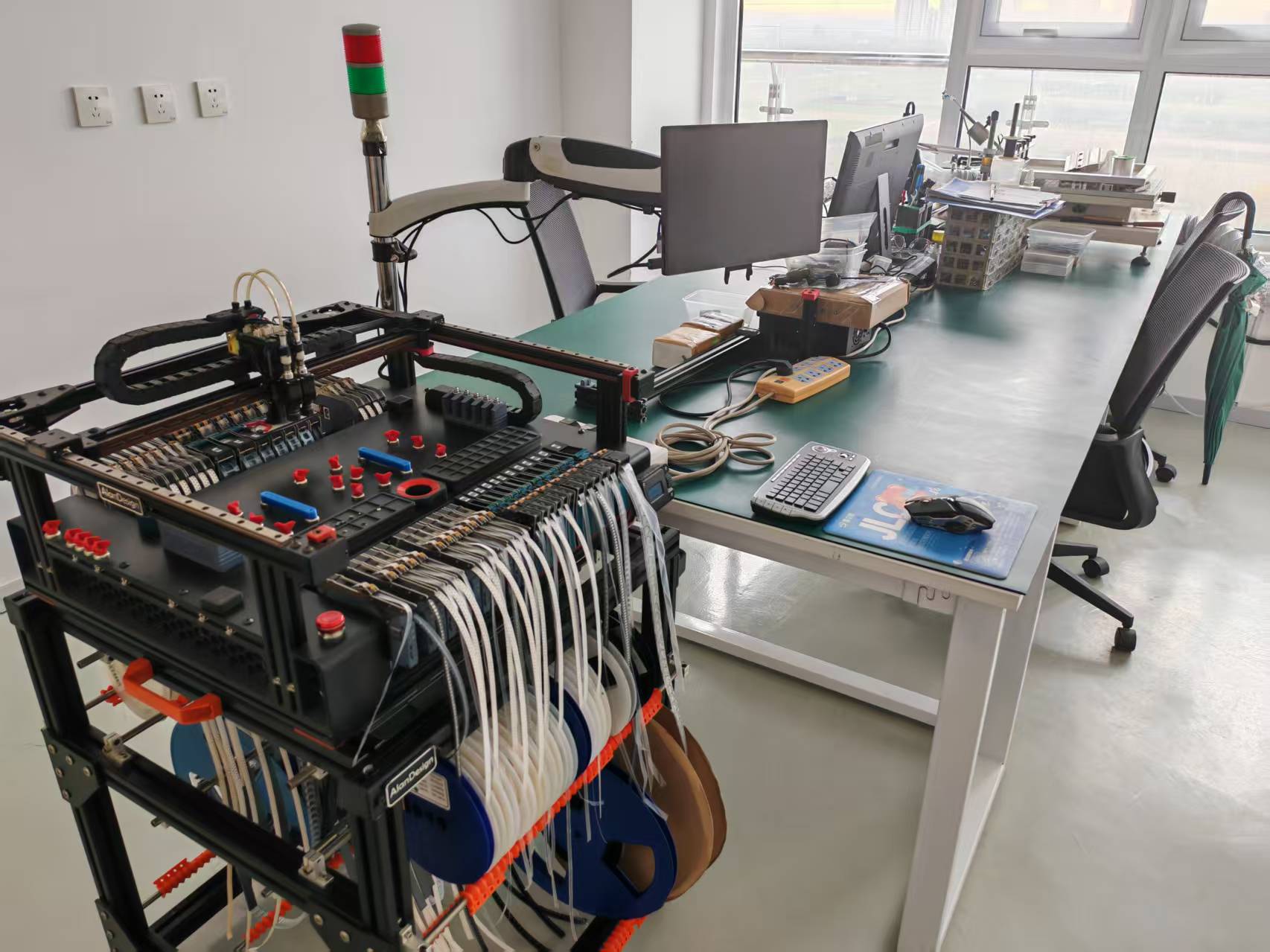

SMT Studio — Building Our Products With Our Own Machines

A major highlight of our new facility is the enhanced SMT Studio, dedicated to assembling the electronic boards for our flagship pick-and-place machines.

We strongly believe that the best way to refine a product is to use it ourselves in real production every single day.

By manufacturing our internal PCB assemblies with our own SMT machines, we can:

Identify practical issues during real-world production

Continuously improve machine performance and user experience

Optimize design through feedback gathered from actual workflows

Maintain a consistently high level of quality and reliability

This philosophy of “build with what we build” has been a core driving force behind every generation of our machines.

Warehouse — Fully Barcode-Driven, Clean and Efficient

The warehouse has been completely upgraded with a full barcode management system, ensuring each material can be tracked efficiently and accurately.

Clean, well-classified shelves and standardized processes enable faster material flow and support stable, efficient production output.。

Comprehensive Equipment Room — Integrated Manufacturing Capabilities

Our equipment room houses a variety of essential production tools, including:

CNC machining center

Drill press

Wire-cutting/stripping machines

Terminal crimping machines

These allow us to complete more manufacturing processes in-house, improving consistency, precision, and turnaround time.

Grand Opening Moments — A Warm Celebration of New Beginnings

To celebrate the move, we held a simple yet joyful opening ceremony.

With decorative signage, a beverage tower, candies, and festive decorations, the atmosphere was cheerful and full of positive energy—a perfect symbol of new beginnings and brighter horizons.

It was a proud moment for the entire team.

A New Beginning With Stronger Momentum

A new space brings new possibilities.

With upgraded facilities, improved workflows, and a more inspiring environment, we remain committed to delivering innovative, reliable solutions worldwide.

Thank you to all customers, partners, and team members for your continuous support.

未来,让我们继续带着自信与热情并肩前行。